المنتجات الساخنة

Coal mill,Coal grinding mill,Crushing mill,Coal powder kiln,Coal

网页Coal Mill. Product specification: Processing capacity: 8-43t/h Processible materials: raw coal. Application range: cement and construction materials production, thermal power

Contact

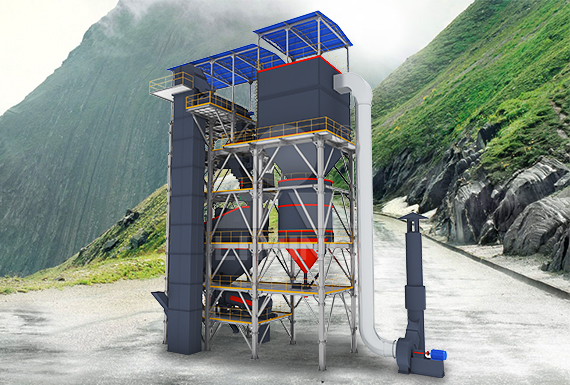

Vertical Coal Mill for Coal Grinding in Cement

网页Vertical coal mill, also known as vertical roller coal mill and vertical coal grinding mill, is a mechanical equipment for crushing and grinding coal

Contact

Coal mill pulverizer in thermal power plants

网页2012年11月16日 2.Coal pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the

Contact

A new model-based approach for power plant Tube-ball mill

网页2014年4月1日 With recently increased penetration of renewable power generation, coal-fired power stations are required to operate more flexibly to serve as peaking load

Contact

Coal Mill in Cement Plant

网页It is a mechanical device used to grind raw coal into pulverized coal powders. The most used coal mills in cement plants are air-swept ball mills and vertical roller mills. At present,

Contact

An intelligent expert system (KBOSS) for power plant coal mill

网页1997年1月1日 This stone describes the development of a knowledge-based mill operator support/control system for coal-pulverising mills. The work described is being performed

Contact

COAL MILL FOR POWER PLANT Crusher Mills

网页In coal-fired power plants coal mills are used to pulverize and dry to coal before it is blown into the power plant furnace. The coal is feed into the coal mill coal mill in thermal

Contact

Drax rules out keeping UK coal plants open this winter

网页2023年6月29日 The Drax power plant near Selby, North Yorkshire. security of electricity supply this coming winter as a contingency measure, and remain committed to ending

Contact

A Modeling and Optimizing Method for Electricity Current

网页2022年2月9日 Coal mills consume a huge amount of station service electricity power of a coal-fired power plant. Meanwhile, the operation of coal mills also has a large influence on boiler combustion. Among all the operating factors, the electricity current intensity of coal mills reflects the electricity power consumption as well as operating status of coal mills. If

Contact

Health indicator construction and application of coal mill

网页2023年5月23日 As the vital auxiliary machine of the coal-fired power plant, monitoring the real-time operating status of coal mills is critical to the secure and stable operation of the power plant. In this study, a new method of construction of the coal mill health indicator (HI) is proposed, and the operation condition monitoring approaches of the device

Contact

Vertical Coal Mill for Coal Grinding in Cement

网页Product Details Working Principle Relevant Projects Technical Data Material Application Vertical Coal Mill Details Vertical coal mill, also known as vertical roller coal mill and vertical coal grinding mill, is a mechanical equipment

Contact

Control for a power plant coal mill pulverizer having

网页Abstract. Power plant boiler fuel demand is transmitted as a coal feeder speed demand to a coal pulverizer control. A speed controller operates the feeder in accordance with the speed demand, and a position controller for a hot coal transport air damper positions the hot air damper to hold the mill outlet temperature to a setpoint value and to increase or

Contact

Online monitoring of coal particle size and flow distribution in coal

网页2016年4月5日 The mills installed at the Gheco-One power plant were designed by Loesche Energy Systems Ltd and are of the LM28.3D type. The internal diameter of the coal feed pipes downstream to the mill is 539.8 mm. This study presents on-line measurement of PCF on a 300 MWe coal-fired power plant with pulsed digital inline holography (DIH). A

Contact

Nova Scotia Power plans to burn heavy fuel oil at phased-out coal

网页2023年7月4日 The 171-megawatt coal-burning plant at Point Aconi in Cape Breton will be retired in 2029. The two coal-fired units at Trenton, with a combined capacity of 311 megawatts, will be retired in 2028

Contact

Coal Mills in Thermal Power Plant PDF Mill (Grinding)

网页2023年6月24日 Bowl mills are employed to pulverize the precrushed raw coal to the required fineness before it is. admitted into the boiler furnace for combustion. The. operating characteristics of bowl mills make it the. best mill available for the direct firing system. of the coal. The best features of all the pulverisers.

Contact

NS Power plans to produce electricity with fuel oil until 2050

网页2023年7月5日 Documents filed by Nova Scotia Power show that three of four coal-fired units at the Lingan Generating Station will be converted to heavy fuel oil in 2030 and are scheduled to operate until 2050

Contact

Coal Pulverizer Maintenance Improves Boiler

网页2015年12月1日 Acceptable standards for best low-NO x burner performance are coal fineness of 75% passing a 200-mesh sieve and less than 0.1% remaining on a 50-mesh sieve. Fuel balance should be within

Contact

The Coal mill performance monitoring SlideShare

网页2019年11月26日 The Coal mill performance monitoring Nov. 26, 2019 • 0 likes • 1,687 views Download Now Download to read offline Engineering The presentation covers the capacity of the coal mill wrt the grindebility index,

Contact

A Modeling and Optimizing Method for Electricity Current

网页2022年2月9日 Introduction Coal mill is an important auxiliary device for coal-fired boilers since it directly influences the boiler combustion. The coal mill grinds the raw coal to a certain fineness, and then, the coal powder is carried to

Contact

Health indicator construction and application of coal mill

网页2023年5月23日 As the vital auxiliary machine of the coal-fired power plant, monitoring the real-time operating status of coal mills is critical to the secure and stable operation of the power plant. In this study, a new method of construction of the coal mill health indicator (HI) is proposed, and the operation condition monitoring approaches of the device

Contact

(PDF) Control for pulverized fuel coal mill

网页2015年10月1日 Most of the thermal power plants in the world are coal fired. They contribute to major part of the world total electric supply. Coal fired plants are known to have low load take up rate and...

Contact

Control for a power plant coal mill pulverizer having

网页Abstract. Power plant boiler fuel demand is transmitted as a coal feeder speed demand to a coal pulverizer control. A speed controller operates the feeder in accordance with the speed demand, and a position controller for a hot coal transport air damper positions the hot air damper to hold the mill outlet temperature to a setpoint value and to increase or

Contact

Coal Mills in Thermal Power Plant PDF Mill (Grinding)

网页2023年6月24日 Bowl mills are employed to pulverize the precrushed raw coal to the required fineness before it is. admitted into the boiler furnace for combustion. The. operating characteristics of bowl mills make it the. best mill available for the direct firing system. of the coal. The best features of all the pulverisers.

Contact

Nova Scotia Power plans to burn heavy fuel oil at phased-out coal

网页2023年7月4日 The 171-megawatt coal-burning plant at Point Aconi in Cape Breton will be retired in 2029. The two coal-fired units at Trenton, with a combined capacity of 311 megawatts, will be retired in 2028

Contact

NS Power plans to produce electricity with fuel oil until 2050

网页2023年7月5日 Documents filed by Nova Scotia Power show that three of four coal-fired units at the Lingan Generating Station will be converted to heavy fuel oil in 2030 and are scheduled to operate until 2050

Contact

Coal Pulverizer Maintenance Improves Boiler

网页2015年12月1日 Acceptable standards for best low-NO x burner performance are coal fineness of 75% passing a 200-mesh sieve and less than 0.1% remaining on a 50-mesh sieve. Fuel balance should be within

Contact

Coal Mill in Power Plant mpl Heavy Industry

网页Speed coal mill power plants must achieve lasting performance for a major overhaul in 3-7 years time, which is crucial for the entire power plant. Therefore, the grinding of pulverized coal in the difficult task, should be

Contact

COAL MILL FOR POWER PLANT Crusher Mills

网页In coal-fired power plants coal mills are used to pulverize and dry to coal before it is blown into the power plant furnace. The coal is feed into the coal mill coal mill in thermal power plant Gulin Solutions coal mill in thermal power plant. Jun 25, 2012 Gulin supply Mining and construction equipment for mineral handling.

Contact